Why corrosion protection is crucial for hose fittings

Hose fittings are among the most heavily stressed components in hydraulic systems. They have to permanently withstand high pressures, temperature fluctuations, vibrations and external influences such as moisture, mechanical loads and aggressive media.

Typical areas of application in which corrosion protection plays a decisive role:

Construction machinery that runs outdoors all year round - from frost to sweltering summer heat

Forestry and agricultural machinery that comes into contact with soil, fertilisers or spraying agents

Offshore facilities or harbour logistics, where salty air creates particularly aggressive conditions

Tunnel boring machines or mining equipment that are exposed to moisture, dust and chemicals underground

Recycling plants in which hose fittings often work in the direct vicinity of corrosive vapours and high temperatures

In all these environments, a long service life counts - the STAUFF zinc/nickel surface makes a significant contribution to this.

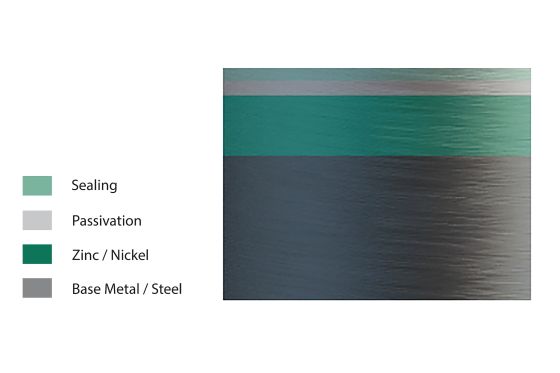

STAUFF zinc/nickel surface at a glance

The zinc/nickel surface was already a long-established standard when the hose fittings were added to our product range in April 2015. It fulfils and exceeds all standard market requirements for corrosion protection and has been used as standard for our steel components since 2007. This is because this special surface is characterised by its very high performance:

Resistance of 1,200 hours (before pressing) against red rust / base metal corrosion in tests in the salt spray chamber in accordance with DIN ES ISO 9227

White rust occurs at most in the form of a light grey haze - and only under extreme conditions

Exceeds the requirements of VDMA corrosion protection class K5 by far

High-quality appearance - for technical cleanliness and visual enhancement

This surface has been proven and valued for years, particularly for applications with high standards - for example in the automotive industry.

Advantages for your application

The use of STAUFF hose fittings with a zinc/nickel surface has numerous advantages that make all the difference in everyday use:

- Increased service life:

The outstanding corrosion resistance permanently protects the fittings from environmental influences. This means significantly longer operating times and less downtime - even under difficult conditions. - Reduced maintenance effort:

As corrosion is virtually eliminated, maintenance and replacement are significantly reduced. This saves costs, time and resources - especially in systems that are difficult to access. - High-quality appearance:

The surface is not only functional, but also visually appealing. This ensures a uniform, high-quality appearance - especially for visible components in machines or systems. - Minimised risk of contact corrosion:

Particularly in systems with mixed connections - such as aluminium or stainless steel - the zinc/nickel surface offers a decisive advantage: it reduces electrochemical reactions and thus protects the entire system. - Overpaintability for individual requirements:

Whether for colour coding, additional protection or adaptation to corporate design - the surface can be easily painted over and is therefore versatile. - Skin-friendly and safe:

Thanks to its extremely low nickel resistance, the allergy risk is well below the legal limits - an important factor in applications where skin contact is possible, e.g. in assembly or maintenance.

Additional assembly advantage: No lubrication necessary

A special advantage of the STAUFF zinc/nickel surface:

No additional lubrication of the threads or cones is required when installing STAUFF hose fittings.

Thanks to special additives in the sealing of the surface, dry assembly is possible - without any loss of tightness or function.

This brings clear advantages for your practice:

Time and cost savings due to elimination of lubricant application

Reduced potential for errors - no incorrect use of lubricant, no assembly errors

No apparent leaks due to residual oil "sweating out" under pressure or temperature

Greater environmental protection, as no lubricant escapes and no residues enter the system

Particularly in automated production lines or with tight time windows in assembly, this aspect provides a real efficiency boost - and reduces environmental pollution at the same time.

Sustainability and environmental standards

The STAUFF zinc/nickel surface fulfils all current environmental and safety requirements - a strong argument, also with regard to ESG targets or legal requirements:

Free from hexavalent chromium (Cr(VI)) - harmless to health and safe to work with

REACH-compliant in accordance with Regulation (EC) No. 1907/2006 - for the safe handling of chemicals

RoHS-compliant in accordance with Directive 2002/95/EC - elimination of hazardous substances in electronic applications

ELV-compliant (2000/53/EC) - especially for the requirements of the automotive industry

This means that the surface is not only functionally strong, but also a sustainable step towards an environmentally conscious future.

FAQs

What advantages does the zinc/nickel surface offer compared to conventional coatings?

Are there any restrictions on the use of coated hose fittings?

No. The surface can be used universally - even with aggressive media or extreme temperatures - and fulfils all relevant standards.

Do I need to lubricate the threads during assembly?

No. Thanks to the special sealing of the surface, dry assembly is possible - completely without lubricant. This saves time, reduces errors and increases environmental friendliness.

Is the quality of the coating checked regularly?

Yes, the finishing is carried out in state-of-the-art facilities with constant monitoring. Tests such as layer thickness measurements, roughness depth and salt spray tests guarantee consistently high quality.

Is the surface harmless to the environment and health?

Yes, the coating is Cr(VI)-free, REACH-, RoHS- and ELV-compliant. It fulfils the highest environmental and safety standards - even for applications with skin contact.

Newsletter registration

Subscribe to the newsletter now and don't miss any new articles!