The 5S program within STAUFF UK focuses on the establishment of visual order, organisation, cleanliness and standardisation in order to improve our profitability, efficiency, service and safety.

This program is part of, and the key component of establishing a Visual Workplace. A system of continual improvement, which is a component of lean manufacturing.

By introducing 5S and involving all departments at every level, STAUFF UK are pleased to be achieving improved profitability, efficiency, service and safety for our employees and ultimately offering improved services to our clients.

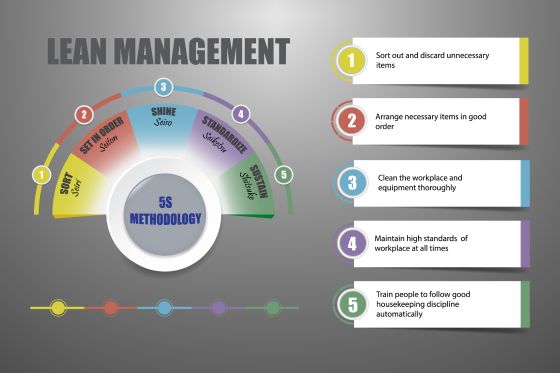

The 5S principles are:

Sort

The first step in making things cleaned up and organised

Set In Order

Organise, identify and arrange everything in a work area

Shine

Regular cleaning and maintenance

Standardise

Make it easy to maintain - simplify and standardise

Sustain

Maintaining what has been accomplished

The implementation of 5S in STAUFF will have the following advantages:

• Reduction of inventory

• Less time used for searching e.g. spare parts and tools

• Reduction of accidents

• Improve working conditions

• Reduction of production stand still