STAUFF UK have developed over many years a centre of excellence at the Carlisle Street East facility, Sheffield, designed to service the requirements of a variety of fluid power industries.

Mobile and industrial hydraulics, offshore oil and gas, transportation, agriculture, construction, access equipment are just some of the customers serviced by the UK Group.

STAUFF UK Tube Manipulation Technology brings its services to OEM, servicing and maintenance clients offering ready to use piece parts or kitted assemblies for “plug and play” just-in-time, line side solutions:

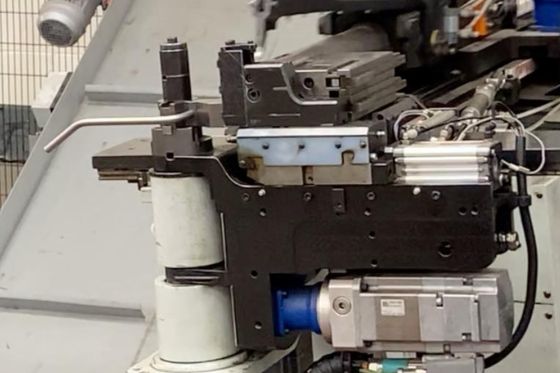

- CNC technology controlled and monitored bending of seamless precision tubes carbon steel (Zistaplex®, Zista® Seal, zinc plated, phosphated, untreated) stainless steel, copper and exotic materials in diameters from 4mm to 101.6mm with varying wall thicknessess depending on material and up to 6 metre lengths

- Automatically controlled and monitored assembly of cutting rings and union nuts

- Tube end forming with STAUFF Form and other common systems

- Inductive soldering, brazing as well as TIG and MIG welding for non-positive connections

- Testing according to standard or customer’s specification

- Cleaning to achieve specific cleanliness levels and specifications

- Sealing and protecting the tube ends and other connections